Abstract

The magnetocaloric effect of Ni50Mn50−xSnx ribbons (x = 11–15) prepared by using melt-spinning and subsequent annealing has been investigated. The x-ray diffraction data of specimens show that all the samples are partially crystallized with Ni2MnSn phase. The magnetic transitions of these ribbons strongly depend on Sn-concentration and annealing process. Particularly, the antiferromagnetic–ferromagnetic transition is just observed at a narrow range of the Sn-concentration (x = 12–14). The positive magnetic entropy changes occurring at the transition temperature of the antiferromagnetic phase are quite large, |ΔSm|max = 5.7 J kg−1 K−1 (for x = 13) with external magnetic field change ΔH = 12 kOe. Besides that, the negative magnetic entropy changes take place near Curie temperature and their magnitude is also large, |ΔSm|max = 1.9 J kg−1 K−1 (for x = 13). The obtained results indicate that Ni50Mn50−xSnx ribbons are good candidates for magnetic refrigeration application at room temperature.

Export citation and abstract BibTeX RIS

Content from this work may be used under the terms of the Creative Commons Attribution 3.0 licence. Any further distribution of this work must maintain attribution to the author(s) and the title of the work, journal citation and DOI.

1. Introduction

Giant magnetocaloric effect (GMCE) of materials is of interest in research by virtue of its application potential in the field of magnetic refrigeration. Magnetic refrigeration is based on the magnetic entropy change principle of materials under variation of magnetic field. The application of magnetocaloric materials in refrigerators has the advantage of avoiding environmental pollution (unlike refrigerators using compression gases), improving the cooling efficiency (saving energy), reducing noise and fitting to some special cases. The main problems to be addressed to improve the practical applications of magnetocaloric materials are: (i) creating GMCE in low field, because it is very difficult to create large magnetic field in civil engineering devices; (ii) performing the magnetic phase transition of materials with GMCE at room temperature; and (iii) extending the working temperature range (range with GMCE) for materials to be cooled in a large temperature range. In addition, some other properties of materials such as heat capacity, electrical conductivity, thermal conductivity, durability and price should be improved for the application of GMCE materials. There are two kinds of GMCE, positive and negative. Both the two effects can be applied in practice and can take place in the same material.

The GMCE in Heusler alloys has been attracting the interest of many scientists [1–9]. Magnetic entropy change (ΔSm) in this kind of magnetocaloric materials is quite large and has both the positive and negative sign. Besides that, the GMCE in the Heusler alloys can be controlled to occur in the room temperature region. The magnetocaloric materials in amorphous or nanocrystalline structure have also been investigated recently [9–12]. The main advantages of amorphous or nanocrystalline materials are capabilities for GMCE, low coercivity, high resistivity, room temperature magnetic phase transition and low cost, which are necessary requirements for practical application. One of the useful methods to fabricate alloys with amorphous or nanocrystalline structure is the rapid quenching technique. In this work, we investigate the magnetocaloric effect of Ni50Mn50−xSnx ribbons (x = 11–15) prepared by means of melt-spinning and subsequently annealing. The goal of this research is to combine the advantages of both the Heusler alloy and rapidly quenched materials for application in magnetic refrigeration.

2. Experimental

The alloys with nominal compositions of Ni50Mn50−xSnx ribbons (x = 11, 12, 13, 14 and 15) were prepared from pure metals (99.9%) of Fe, Ni and Sn. Arc-melting method was first used to ensure the homogeneity of the alloys. Melt-spinning method was then used to fabricate the ribbon samples. Thickness of the ribbons is about 30 μm. Some of the ribbons were annealed at various annealing temperatures (Ta) and time (ta) in vacuum. The structure of the samples was examined by powder x-ray diffraction (XRD) method. The magnetic and magnetocaloric properties of the samples were characterized by magnetization measurements.

3. Results and discussion

Figure 1 shows typical XRD patterns of Ni50Mn50−xSnx alloy ribbons before and after annealing at 1123 K for 5 h. XRD patterns of the as-quenched ribbons reveal two main diffraction peaks corresponding to Ni2MnSn phase (austenitic L21-cubic structure) and look very similar as the Sn-concentration (x) varies. However, the diffraction peaks of the main crystalline phase (Ni2MnSn) slightly shift to higher values of the 2θ when Sn-concentration is increased (see the inset of figure 1(a)). That means lattice constants of the crystal are changed by Sn-concentration. The change of the lattice constants probably leads to a variation of magnetic orders in the alloys as presented below. After annealing at 1123 K for 5 h, the structure of all the ribbons is clearly different from that of the as-quenched ones. Other crystalline phases such as Ni3Sn2 and Mn1.77Sn are formed. The number and intensity of the diffraction peaks of these annealed ribbons is dependent on Sn-concentration.

Figure 1. XRD patterns of Ni50Mn50−xSnx alloy ribbons: (a) as-quenched and (b) annealed at 1123 K for 5 h.

Download figure:

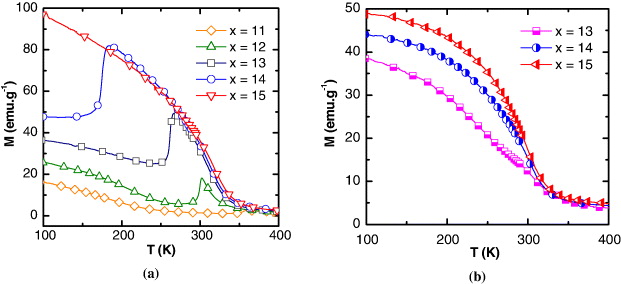

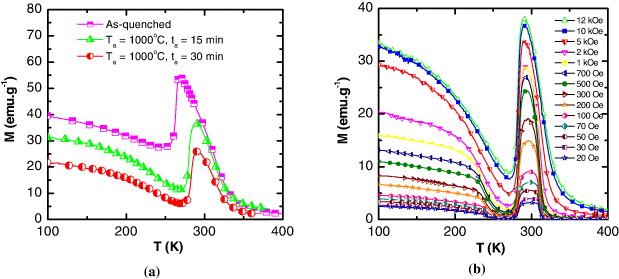

Standard image High-resolution imageMagnetic properties of the alloys were investigated by magnetization measurements. Magnetic hysteresis measurement indicates that all the as-quenched and annealed ribbons are soft magnetic. The thermomagnetization measurement reveals the magnetic phase transitions in the ribbons. Figure 2 presents thermomagnetization curves in an applied magnetic field of 12 kOe of Ni50Mn50−xSnx alloy ribbons before and after annealing at 1123 K for 5 h. In as-quenched state, the alloy has an antiferromagnetic–ferromagnetic (AFM–FM) transition. The temperature (TP) and magnitude of the AFM–FM transition strongly depends on Sn-concentration. The TP of the alloy is fast decreased from 302 to 182 K by an increase of 2 at.% of the Sn-concentration (from 12 to 14 at.%). The AFM–FM transition of the samples with Sn-concentrations of 11 and 15 at.% is not observed in the temperature range of 100–350 K. Thus, the AFM order, which relates to a martensite 10 M-orthorhombic structure, is very sensitive to the Sn-concentration in the alloy. The AFM–FM transition greatly affects on magnetocaloric effect of the alloy as shown later. After annealing at 1123 K for 5 h, no AFM–FM transition is observed in the ribbons with all the Sn-concentrations, while the ferromagnetic–paramagnetic (FM–PM) transition (TC) occuring near 330 K is almost unchanged by this annealing process (figure 2(b)). Nevertheless, the AFM–FM transition still exists in the samples annealed at 1273 K for 15 and 30 min (figure 3(a)). By increasing the annealing time, the TP is shifted to higher temperatures, the TC is nearly unchanged and the magnetization is decreased.

Figure 2. Thermomagnetization curves in an applied magnetic field of 12 kOe of Ni50Mn50−xSnx alloy ribbons: (a) as-quenched and (b) annealed at 1123 K for 5 h.

Download figure:

Standard image High-resolution imageFigure 3. Thermomagnetization curves of Ni50Mn37Sn13 alloy ribbons: (a) for as-quenched and annealed (at 1273 K for 15 and 30 min) samples measured in magnetic field of 12 kOe and (b) for the sample annealed at 1273 K for 15 min measured in various magnetic fields.

Download figure:

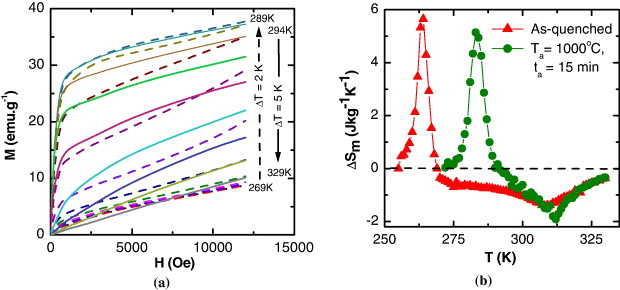

Standard image High-resolution imageFigure 3(b) shows thermomagnetization (M–T) curves in various magnetic field of Ni50Mn37Sn13 (x = 13) alloy ribbons annealed at 1273 K for 15 min. From these M–T curves, the magnetization versus magnetic field (M–H) curves (figure 4(a)) can be deduced. Based on M–H curves, magnetic entropy change (ΔSm) can be calculated by using Maxwell's relation

Figure 4. Magnetic field dependence of magnetization at various temperatures of an as-quenched Ni50Mn37Sn13 alloy ribbon (a) and temperature dependence of magnetic entropy change in 12 kOe magnetic field variation of this sample before and after annealing at 1273 K for 15 min (b).

Download figure:

Standard image High-resolution imageTemperature dependence of the magnetic entropy change (ΔSm–T) in a 12 kOe-magnetic field variation of the Ni50Mn37Sn13 sample before and after annealing at 1273 K for 15 min is presented in figure 4(b). The ΔSm–T curves of both the two samples have two extrema with opposite signs. One extremum corresponds to the maximum of the magnitude of the positive GMCE and the other is of the negative GMCE. The positive GMCE is due to the AFM–FM transition and the negative GMCE is related to the FM–PM transition in the materials. The maximum positive and negative magnetic entropy changes are quite large: |ΔSm|max = 5.7 J kg−1 K−1 and | − ΔSm|max = 1.4 J kg−1 K−1 for the as-quenched sample, |ΔSm|max = 5.2 J kg−1 K−1 and | − ΔSm|max = 1.9 J kg−1 K−1 for the annealed sample.

It should be noted that by appropriate annealing processes, both the maximum magnetic entropy change and full-width at half-maximum of the magnetic entropy change of the ribbons can be regulated in room temperature region. One can see in figure 4(b) that by annealing at 1273 K for 15 min, the maximum positive magnetic entropy change of the Ni50Mn37Sn13 alloy ribbon is shifted from ∼265 to ∼285 K and the maximum negative magnetic entropy change of this sample, which occurs at ∼310 K, increases from 1.4 to 1.9 J kg−1 K−1. The full-width at half-maximum of the negative magnetic entropy change of the ribbons is quite large (>20 K). Both the positive and negative magnetocaloric effects of the ribbons take place quite closely in room temperature region. Thus, it is possible for combining all the positive and negative magnetocaloric effects of the material for magnetic refrigeration application at room temperature. The influence of annealing conditions on magnetocaloric effect of the Ni–Mn–Sn ribbons needs to be studied further to achieve an optimum of this effect for practical applications.

4. Conclusion

The magnetic and magnetocaloric properties of the Ni50Mn50−xSnx ribbons strongly depend on Sn-concentration and annealing process. The AFM–FM transition of the alloy is just observed at a narrow range of the Sn-concentration (x = 12–14) and can be controlled by the annealing process. Both the positive and negative magnetic entropy changes are quite large, |ΔSm|max > 5.2 J kg−1 K−1 and | − ΔSm|max >1.4 J kg−1 K−1 with external magnetic field change ΔH = 12 kOe. The full-width at half-maximum of the magnetic entropy change is also large making Ni50Mn50−xSnx ribbons possible for application in magnetic refrigeration.

Acknowledgments

This work was supported by the National Foundation for Science and Technology Development (NAFOSTED) of Vietnam under grant number of 103.02-2011.23 and the Converging Research Center Program funded by the Ministry of Education, Science and Technology (2012K001431), South Korea. A part of the work was done in the Key Laboratory for Electronic Materials and Devices, and Laboratory of Magnetism and Superconductivity, Institute of Materials Science, VAST.