Abstract

Experimental studies on polymer materials with spatially graded structures are reviewed in this paper. A wide variety of principles and experimental methods utilized to prepare and control these specific structures of polymer materials are summarized and discussed. In particular, the method of using light to generate and control these gradient morphologies in the micrometer scales is summarized with great detail for binary polymer mixtures. Finally, recent studies on copolymers with various gradient compositions at nanometer length scales are also summarized in this review.

Export citation and abstract BibTeX RIS

Content from this work may be used under the terms of the Creative Commons Attribution-NonCommercial-ShareAlike 3.0 licence. Any further distribution of this work must maintain attribution to the author(s) and the title of the work, journal citation and DOI.

1. Introduction

In nature and materials processing at large scales, most of the kinetic processes often proceed non-uniformly both in space and time. As a consequence, hierarchical structures and/or morphologies with multiple length scales emerge as a 'footprint' of these dynamic inhomogeneities. From the viewpoint of polymer materials, it would be useful if one could take advantages of this inhomogeneity to control, at will, the distribution of two-dimensional (2D) and/or 3D properties of polymers, such as wettability or elastic modulus. As far as gradient materials are concerned, there exist two research directions: polymeric and non-polymeric materials. The pioneered research on gradient polymers was initiated in the early 1970s by Beaver and Duwez, and later extensively developed by Shen [1], who suggested the method of fabricating gradient polymers via diffusion followed by polymerization of monomers in cross-linked polymer matrices. These methods provided materials for utilization at moderate temperatures due to the nature of synthetic polymers. In the 1980s, the second research direction on functionalized graded materials was initiated in Japan. These developments stemmed from the demand for materials used at high temperature, mostly in aviation engineering, where the temperature difference between two sides of a material might increase by more than 1000 °C [2, 3].

Here, the preparation and characterization of these gradient polymers will be briefly reviewed. First, studies on polymers with a composition gradient generated by diffusion of a given monomer followed by its polymerization in the cross-linked matrix of the second polymer will be described together with their resulting physical properties. Subsequently, the methods taking advantage of phase separation induced by introducing a gradient of a quench depth will be summarized. This quench depth was built into the mixture either by a gradient of temperature or a concentration gradient via heat, or by UV light irradiation. A similar strategy of building a composition gradient along a block copolymer molecule by chemical synthesis is also briefly introduced and compared to other experimental techniques. Finally, as a general method to design and produce polymers with spatially graded morphologies, the advantages of using the so-called computer-assisted irradiation (CAI) method [4] in light-induced phase separation will be discussed in conjunction with the spatio-temporal control of phase separation of polymer blends.

2. Experimental studies on gradient polymers

2.1. Gradient polymers prepared by diffusion associated with polymerization

Shen's and Bever's research groups were among the first to report this method based on a diffusion–polymerization mechanism. As early as 1976, Shen and co-workers showed that by applying the diffusion followed by polymerization of acrylonitrile into poly(methyl methacrylate), and methyl acrylate into poly(methyl methacrylate), the resulting polymer composites exhibit a high resistivity to hydrocarbon solvents and also an increase in fracture strain [5]. These results reveal the ability of toughening polymer materials of gradient polymers compared to the corresponding uniform materials. For diffusion followed by the polymerization process in the synthesis of gradient polymers, the glass transition temperature of the polymer matrix into which a monomer was allowed to diffuse, plays an important role in the diffusion mechanism of the monomer. Shen and co-workers showed the two distinct cases for this monomer diffusion associated with polymerization [6]. 2-chloroethyl acrylate, the monomer of a polymer having a fairly low glass transition temperature ( T g ≈−25 ° C), was allowed to diffuse into poly(methyl methacrylate) with a much higher temperature ( T g ≈ 100 ° C). It was found that 2-chloroethyl acrylate exhibits the behavior of the diffusion case II [7] in a PMMA matrix. On the other hand, methyl methacrylate, the monomer of the polymer with a higher Tg , follows the Fickian diffusion behavior upon diffusing into the poly(2-chloroethyl acrylate) (PCEA) matrix with a much lower glass transition temperature. Unfortunately, the information on the phase separation and morphology of these polymer composites was not available. Since then, gradient polymers from various polymer pairs, such as poly(butyl acrylate)/cross-linked polystyrene [8] and gradient poly (methyl acrylate) in cross-linked polystyrene matrix [9], were fabricated, demonstrating the superior properties, such as higher modulus, retaining plasticity at higher temperatures of these gradient composites compared to composites prepared by uniform techniques. Gradient polymers containing poly(vinyl chloride) (PVC) and poly(methyl methacrylate) (PMMA) were also fabricated by keeping a PVC film in contact with a solution containing PMMA. By dissolving PVC film using the PMMA solution, mutual diffusion between PVC and PMMA occurs, leading to the formation of various composition gradients of PVC inside the PMMA solution. Finally, polymer composites containing various composition gradients of PVC and PMMA were obtained [10]. To produce polymer materials with a gradient in mechanical properties, instead of taking advantage of the concentration gradient generated by diffusion, a gradient of light intensity was recently used to induce photopolymerization and photo-crosslink reactions. By irradiation from one side of the sample, the properties of the sample become asymmetric, dissimilating the front and back sides of the samples [11].

In contrast to the above-mentioned methods of fabricating a gradient along the direction of the sample thickness, several efforts have been made to produce the lateral gradients of concentration. The method of 'solution-diffusion' was applied to polystyrene/styrene-hydrogenated butadiene-styrene block copolymers (SEBS) for this purpose [12]. Polymers with gradient structures developing during the shear processing were also reported recently [13].

Besides the methods relying on diffusion followed by polymerization described above, coupling a temperature gradient to phase separation of a binary polymer mixture has been utilized to produce and control the morphology of a binary polymer mixture, poly(2-chlorostyrene)/poly(vinyl methyl ether) (P2CS/PVME) [14]. This method bears some resemblance to the materials processing method based on the directional solidification of metallic alloys or binary mixtures [15] where the mixture was set in a temperature gradient with two temperature ends covering the two sides of the phase diagram of the LCST (lower critical solution temperature) type. Phase separation of this polymer mixture was induced and driven by increasing the temperature gradient with time at a constant rate. As a result, the interfaces between the miscible and two-phase regions were dragged toward the lower temperature side, while the phase separation process was observed by phase-contrast optical microscopy. It was found that the resulting graded morphology became more anisotropic with smaller characteristic length scales along the temperature gradient. The morphological anisotropy becomes less significant toward the higher temperature side. These experimental data are qualitatively in accordance with the prediction from computer simulation [16].

2.2. Gradient polymers prepared by light-induced phase separation

2.2.1. Principle and method

Most of experiments performed for the fabrication of graded polymers have strongly relied on manipulating the spatial distribution of composition in multi-component polymers by diffusion followed by the polymerization method. From the thermodynamic viewpoint, the polymer mixture would be destabilized by the internal polymerization of a deposited monomer. This instability might lead to phase separation, which could destroy the composition gradients of monomers intentionally preset in the host polymer by diffusion or sorption. As a new approach, phase separation induced by chemical reaction was undertaken as a strategy for producing polymers with spatially graded structures.

Depending on the driving force for the chemical reactions in use, there are two ways to induce and control the spatially graded morphologies of multi-component polymers: thermally induced and reaction-induced phase separation. In general, compared to heat, light can be efficiently used as a useful tool to drive the phase separation both spatially and/or temporally. In this section, we will mainly review our recent achievements in using photochemical reactions to drive the phase separation of polymer mixtures under non-uniform conditions to generate various spatially graded structures.

The driving force for the formation of these graded morphologies originated from a gradient of quench depth, which can be induced either by a gradient of light intensity or by a temperature gradient set across the mixture. For polymeric materials, the former is easily generated by taking advantage of the Lambert–Beer law, whereas the latter is limited by the relatively low thermal decomposition of polymeric materials. The gradient of light intensity in the irradiation process is therefore used to produce a gradient of reaction yield, which, in turn, leads to a gradient of quench depth in the polymer mixture under investigation.

For this purpose, appropriate photochemical reactions must be used. In our case, photodimerization of anthracene was utilized to control the quench depth and, consequently, the characteristic length scales of the morphology [17]. As illustrated in Scheme 1, anthracene was chemically labeled as a photo-cross-linker on one polymer component in a binary polymer mixture. In order to carry out 3D imaging of the transient morphology developing in the reacting mixture, the same polymer is also chemically labeled with a fluorescent marker, which allows the discrimination of that polymer component from the rest in the binary mixture.

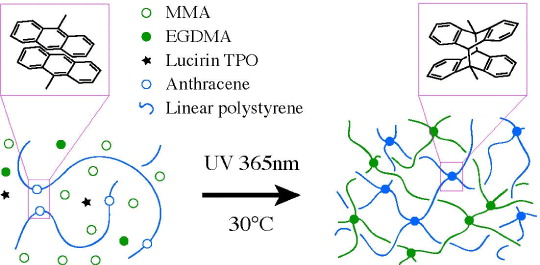

Scheme 1 Procedure for the chemical synthesis of polystyrene-poly(methyl methacrylate) full-interpenetrating polymer networks (IPNs) using photo-cross-link and photopolymerization.

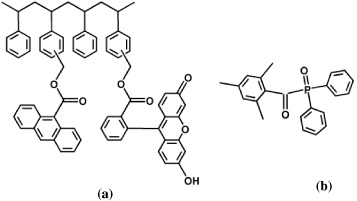

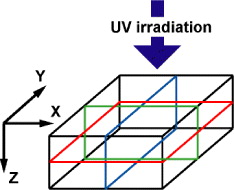

An example for the chemical structure of such a doubly labeled polymer is shown in figure 1, where a polystyrene derivative was chemically labeled with both anthracene as a photo-cross-linker and fluorescein as a fluorescent marker. In general, one component can be chemically designed so that the polymer chain bears two functional groups: one serves as a reacting group, such as anthracene or coumarin [18], and another is used as a non-reactive fluorescent marker for morphology imaging by laser-scanning confocal microscopy (LSCM). The geometry for morphological observation under LCSM is illustrated in figure 2, where UV was impinged from above along the Z-direction. The co-continuous morphology resulting from irradiation was analyzed by a 2D fast Fourier transform (2D-FFT), whereas for the case of the droplet morphology, the characteristic length scales were obtained by digital image analysis techniques [19]. Phase separation kinetics were deduced from the irradiation-time dependence of these characteristic length scales.

Figure 1 Chemical structure of (a) polystyrene doubly labeled with anthracene and fluorecein (PSAF) and (b) the photoinitiator Lucirin TPO.

Figure 2 The coordinate system for UV irradiation and morphology observation by laser-scanning confocal microscopy (LSCM).

2.2.2. Samples

Polymers with spatially graded structures were prepared from the mixtures of polystyrene derivative doubly labeled with anthracene and fluorescein (PSAF) and methyl methacrylate (MMA) monomer containing various concentrations of ethyleneglycol dimethacrylate (EGDMA), the cross-linker for the PMMA component. Upon irradiation with UV light (365 nm) at ambient temperature, the PSAF component was cross-linked by photo-dimerization of anthracene, whereas the monomer MMA was photo-polymerized in the presence of Lucirin-TPO used as an initiator and was also cross-linked by using EGDMA. The length scale of the resulting morphology can be easily manipulated by controlling the content of the photo-cross-linker anthracene on the PSAF and/or the concentration of the cross-linker EGDMA for the PMMA components. The UV light intensity is also a control parameter for the resulting morphology.

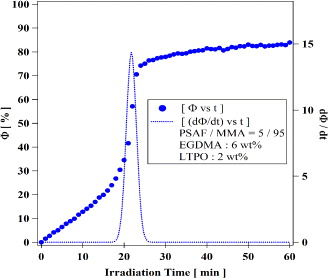

2.2.3. Autoacceleration behavior of the polymerization reaction in the mixtures

Polymerization kinetics of the monomer MMA in the mixture exhibits autocatalytic behavior, the so-called Tromsdorff effects [20], as illustrated in figure 3 for a mixture of methyl methacrylate (MMA) and polystyrene doubly labeled with anthracene and fluorescein (PSAF). As the polymerization proceeds, it is accelerated by itself, as evidenced by a sharp peak obtained by the derivative of reaction yield ϕ with respect to irradiation time.

Figure 3 Photopolymerization and photo-cross-link kinetics of methyl methacrylate (MMA) in a PSAF/MMA (5/95) mixture in situ monitored by FT-IR at 25 °C [32].

This autocatalytic behavior originates from the positive feedback loop driven by the increase in heat generated by the reaction and in viscosity as a consequence of an increase in molecular weight. Eventually, the polymerization is terminated by the high viscosity of the mixture. Due to this autocatalytic behavior of the reaction, the triggered phase separation process also becomes autocatalytic, as described later.

2.2.4. Spatially graded polymer materials generated by UV irradiation

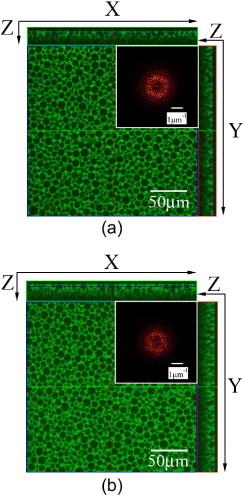

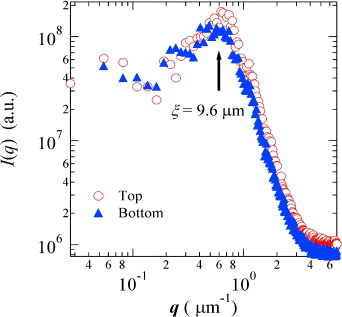

Under irradiation with UV light of weak intensity, a PSAF/MMA (10/90) mixture undergoes phase separation, exhibiting spatially uniform morphology. An example is shown in figure 4. Here, the droplet morphologies observed at the two focal planes located at 4 μm apart from the top and bottom surfaces of the mixture are almost the same as revealed by the 1D Fourier intensity distribution shown in figure 5. Upon increasing the light intensity, the difference in the morphological length scales emerging at the top and bottom of the sample becomes significant, indicating that graded structures can be designed by this experimental strategy [21].

Figure 4 Cross-section of a PSAF/MMA (10/90) mixture irradiated with 365 nm over 60 min at 30 ° C: (a) at 4 μm from the front; (b) at 4 μm from the backside. The 2D-FFT power spectra corresponding to each case are illustrated in the inset.

Figure 5 1D-FFT power spectra of a PSAF/MMA (10/90) mixture observed at a distance of 4 μm from the surface of both sides of a PSAF/MMA (10/90) mixture photo-cross-linked in 60 min with 365 nm UV light [21].

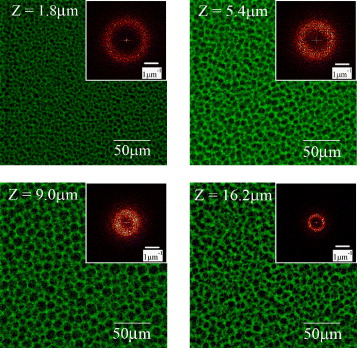

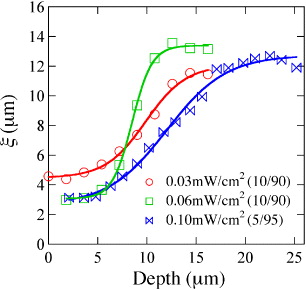

An example is shown in figure 6, where the graded morphology emerges and develops along the Z-direction upon irradiation with an intensity 0.03 mW cm −2 as clearly revealed by the decrease in radius of the 'Fourier ring' depicted in the corresponding inset of each micrograph. The irradiation intensity-dependence of the gradient structures of these mixtures is summarized in figure 7. A feature of these graded morphologies is that their gradient does not vary linearly with the depth of the sample.

Figure 6 Graded co-continuous morphology observed at different depths in a PSAF/MMA (10/90) mixture irradiated with 0.03 mW cm −2 UV light at room temperature. The number in the figure indicates the Z-coordinate of the (X–Y) plane of observation. The corresponding 2D-FFT power spectra are illustrated in the inset [21].

Figure 7 The depth-dependence of the morphology observed for a PSAF/MMA (10/90) and PSAF/MMA(5/95) mixture at 30 ° C under different irradiation intensities [21].

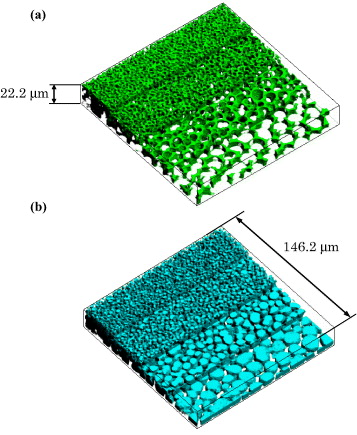

Instead, the characteristic length scales in the vicinity of the cover glass become unchanged with the light intensity due to the wetting phenomena. The 3D graded morphology of a PSAF/MMA (5/95) mixture obtained by irradiation with an intensity of 0.1 mW cm −2 at 365 nm is illustrated in figure 8, where both the PSAF and PMMA components of the same morphology are separately shown in the same figure.

Figure 8 3D graded morphology obtained by LCSM for PSA/PMMA (5/95) full-IPNs (Interpenetrating Polymer Networks) obtained by irradiation with 0.1 mW cm −2 UV light of 365 nm. The morphologies were constructed by stacking the 2D data monitored at different depths. (a) Only the PSAF-rich component is illustrated; (b) only the PMMA-rich component is shown using contrast inversion. The PSAF-rich phase is continuous, whereas the PMMA-rich phase is partially continuous.

Obviously, the PSAF-rich component forms a continuous phase over the entire sample thickness, whereas the PMMA-rich phase is partially continuous. The continuity of the PMMA-rich phase reveals the 'cluster-to-percolation' transition, which has been often observed in polymeric systems undergoing phase separation induced by polymerization [23]. Namely, after passing through the spinodal region, the whole mixture enters the nucleation-and-growth region, resulting in droplets with different sizes. Unlike the non-reacting mixtures, the polymerization of MMA continues after phase separation, creating more PMMA in the mixture. Since PMMA is not dissolved in PSAF-rich domains, further polymerization of MMA could lead to the interconnection among the PMMA-rich dispersed phases in the materials.

Another feature of the graded morphology induced by photopolymerization and photo-cross-link is that depending on the changes in the phase boundary with respect to the state of the mixture, the morphological length scales could decrease along the gradient of the irradiation intensity, instead of increasing. These results would be in contrast with the results observed in figure 6, suggesting that the resulting graded morphologies are determined by both the reaction kinetics and the thermodynamics modified by chemical reactions. The morphology of poly(n-butyl acrylate)/(methyl methacrylate) mixtures under irradiation with high UV intensity is an example for this particular case [22].

2.2.5. Autoacceleration behavior of phase separation induced by photo-polymerization

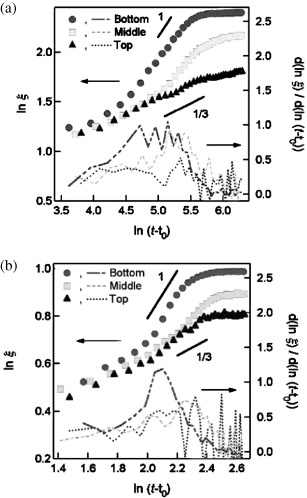

Polymer mixtures undergoing reaction-induced phase separation can be regarded as stimulus–response systems. Polymerization is a stimulus, whereas phase separation corresponds to the response of the system. As seen in figure 3 above, since the polymerization of the MMA monomer exhibits autocatalytic behavior, it would be interesting to examine the behavior of phase separation, the response of the mixture, corresponding to this stimulus. By using LSCM, the phase separation of a PSAF/MMA (10/90) mixture was in situ followed and the characteristic length scale ξ was plotted versus the time of phase separation defined as (t−t0) in figure 9. The irradiation time derivative of the characteristic length scales with respect to (t−t0) shown on the right-hand side reveals the stimulus–response behavior of the mixture. Within the irradiation time, the phase separation kinetics varies between the two limits Liftshitz–Slyosov (ξ ∼t1/3) [24, 25] and Siggia (ξ ∼t1) [26]. On the top and middle positions of the mixture, the length scale ξ of the morphology slowly increases with irradiation time, whereas ξ is strongly enhanced at the bottom position. The derivative exhibits a maximum that corresponds to the inflection point on the versus curve, revealing the existence of an inflection point. In other words, the self-acceleration of the polymerization of MMA induces autocatalytic behavior of the phase separation process. These experimental results suggest that the autocatalytic reaction triggers autocatalytic phase separation.

Figure 9 Autocatalytic behavior of phase separation kinetics observed in a PSAF/MMA (10/90) mixture irradiated with two intensities: (a) 0.03 mW cm −2; (b) 0.06 mW cm −2.

2.3. Gradient (tapered) copolymers: developments and application

With the development of chemical synthesis, such as living (anionic, cationic and radical [27]) polymerization, the molecular design of polymers has taken a great step forward. Here, typical research on tapered (or gradient) copolymers will be briefly mentioned. Since polymer–polymer miscibility is very low even at the macroscopic level, many attempts to mix different polymers at the molecular level have been made since the 1950s. Interpenetrating polymer networks (IPNs), copolymers and graft polymers are the achievements of these efforts. Similar to the correlation between polymer blends and copolymers, gradient (tapered) copolymers were developed in contrast to gradient polymer blends. In the former, composition gradients were built by chemical reactions along the polymer chain, whereas macroscopic composition is generated by physical and chemical techniques, as described in sections 2.1 and 2.2.

Tapered blocks were studied in the 1980 s and were refined recently, thanks to the development of chemical synthesis. Tapered blocks were designed with the aim of modifying the interfacial energy and thus compatibility between different polymer components, the order–disorder transition temperature, etc. So far, these synthesized tapered blocks have discontinuous composition along the polymer chains. Recently, using controlled free radical polymerization, Northwestern University (Illinois, USA) has developed various gradient copolymers in which the composition of monomers gradually changes along the polymer chain [28]. It has been shown that these gradient copolymers can be used as a compatibilizer, which works much better compared to random copolymers [29]. Fundamental properties of these gradient copolymers, such as relaxation, have been studied and also used to control polymer surface properties [30], and in liquid/liquid interfaces studies [31].

3. Conclusion

Polymers with spatially graded structures are useful and important for materials science, particularly when materials with continuously and gradually changing physical properties are required. By combination with new chemical synthesis, these gradient polymers could be important for materials science in the near future. Since the physical properties of these gradient materials can be strongly modified by the composition of their constituents, if the spatial distribution of composition can be manipulated at will, much more functional materials can be designed for particular purposes. For light-induced phase separation, the computer-assisted irradiation (CAI) method described above could provide a tool to design polymers with an arbitrary composition.

Acknowledgments

This work was supported by the Ministry of Education (MONKASHO), Japan, through the Grant-in-Aid for Scientific Research type B (No. 20350107) and the Grant-in-Aid No. 19031018 for the Priority-Research-Area No. 463 'Soft Matter Physics'. V-PD-T would like to thank MONKASHO for the scholarship to pursue the PhD program at Kyoto Institute of Technology, Kyoto, Japan.