Abstract

Cobalt nanowires with different shape parameters were synthesized via the polyol process. By calculating the magnetic energy product (BHmax) both for dried nano-powder and for nanowires in their synthesis solution, we observed unexpected independent BHmax values from the nanowires shape. A good alignment of the nanowires leads to a higher BHmax value. Our results show that the key parameter driving the magnetic energy product of the cobalt nanowires is the stacking fault density. An exponential collapse of the magnetic energy is observed at very low percentage of structural faults. Cobalt nanowires with almost perfect hcp crystalline structures should present high magnetic energy, which is promising for application in rare earth-free permanent magnets.

Export citation and abstract BibTeX RIS

Original content from this work may be used under the terms of the Creative Commons Attribution 3.0 licence. Any further distribution of this work must maintain attribution to the author(s) and the title of the work, journal citation and DOI.

1. Introduction

A good understanding of the correlation between the structural and magnetic properties of Co-based nanostructures is mandatory for the improvement of their applications in magnetic recording media [1–3], as well as in permanent magnet systems [4–6]. In both kinds of applications high magnetocrystalline anisotropy is crucial in order to maintain stability in the written information and high energy product. Thus, a cobalt pure hexagonal close-packed (hcp-cobalt) structure is strongly required for maximizing this magnetocrystalline anisotropy as it shows (compared to the cobalt cubic one) the highest anisotropy constant (i.e. in bulk k1 = 450 kJ m−3). Unfortunately, the hcp-cobalt structure is also known to easily present regular occurrence of growth faulting [7, 8]. A stacking fault in the hcp structure creates layers of atoms presenting a face-centered cubic (fcc) symmetry which is magnetically more isotropic (i.e. in bulk k1 = 63 kJ m−3). Three different kinds of stacking faults are commonly observed to occur: intrinsic, extrinsic and twin-like types [9]. They have a detrimental overall effect on the magnetic properties of Co-based hexagonal systems, usually resulting in a macroscopic lower anisotropy and thus in a magnetic softening [10, 11]. Theoretical studies [9] demonstrated that the magnetocrystalline anisotropy energy (MAE) in a hcp-Co structure strongly depends on the probability and type of growth faulting. The dependence appears not to be simply the sum of the changes in the magnetocrystalline anisotropy energy due to each individual stacking fault. In fact, the long-ranged oscillations predicted in the MAE by the presence of each stacking fault indicate that the situation is far more complex. This long-ranged behavior could give rise to significant finite-size effects in nano-sized samples and have strong consequences on their magnetic properties. Experimentally, the presence of stacking faults is normally quantified in terms of the stacking fault density, which is partly a measure of how close the stacking faults are located. This long-range behavior suggests that in small systems, even for low density of stacking faults, the effect of the local breaking of the uniaxial symmetry should reduce the magnetic anisotropy, causing thermal instability and low switching field.

Sokalski et al [12] experimentally found on Co-based thin films a strong linear decrease of the uniaxial anisotropy constant versus the increasing c-axis value. Such a trend was already reported previously in the literature [13, 14] and qualitatively consistent with bulk measurements of magnetostriction for cobalt single crystal, where a compression of the c-axis increases the magnetic anisotropy. However, they found a clear non-linear dependence of the magnetic anisotropy constant on the stacking fault density indicating that these could have an indirect effect on magnetic anisotropy via their influence on the crystallographic lattice parameter. Mai et al [15] found in CoNi nanowires a linear dependence of the coercive field on the stacking faults density. In this work the shape contribution to the switching field has been kept constant, thus suggesting a linear correlation of the magnetocrystalline contribution with the density of stacking faults. It is also worth mentioning that in some hexagonal Cobalt nano-alloys (e.g. SmCo5.7) [16, 17] small amounts of defects seem to improve the magnetic properties. All these results suggest that the influence of the stacking fault effects on the properties of metal nanostructures is quite controversial.

Keeping in mind the potential application of cobalt nanowires as building blocks in permanent magnets that is clearly connected with the mandatory optimization of their magnetic energy product and anisotropy, we address here the complete study of the stacking fault effects over the magnetic energy of hcp-cobalt nanowires. Our results indicate that the stacking faults induced by the elaboration conditions strongly determine the structural and magnetic properties of hcp-Co. Comparing our results to the recent ones of Gandha et al [18] on the effect of shape dispersion on the maximization of the magnetic energy product, we could hence conclude that appropriate control of the stacking faults can lead to the improvement of the magnetic properties much stronger than the shape anisotropy.

2. Experimental

Cobalt nanowires were prepared by the reduction of metallic salts in a liquid polyol [19, 20]. This method allows accurate control of the nanoparticles' size and morphology via kinetic control of the growth step [21]. The nanowires' powder was separated from the solution by centrifugation washed several times by ethanol and then dried in a vacuum oven at 50 °C. Standard TEM imaging has been performed by using JEOL-2011 operating at 200 kV for all the elaborated systems in order to study the morphology and size dispersion of the nano-objects. Four morphological parameters have been taken into account: the diameter (D), the length (L), the width of the head (W), and the thickness (T) of the head (see figure 1(b)). Accurate measurements of these four morphological parameters have been performed by measuring more than 150 pictured nanowires per batch. The crystallographic structure and density of stacking faults have been characterized by x-ray diffraction (XRD) patterns (not shown here) recorded with a PANalytical Empyrean diffractometer equipped with Cu-Kα x-ray source (λ = 1.5406 Å). Elaboration details as well as TEM and XRD analyses will be published elsewhere [22]. The magnetic energy product of the Co nanowires has been calculated from the static magnetic measurements using a Quantum Design MPMS 3 magnetometer. For this purpose we recorded magnetic hysteresis cycles by field cooling (FC) the samples under the application of H = 70 kOe at different temperatures. For each batch (i.e. each morphology), we measured the magnetic properties of the nanowires inside their synthesis solution (polyol) and their corresponding dried powder. In the case of nanowires inside the polyol solution, the FC procedure allows a huge percentage of nanowires aligning along the applied magnetic field before the polyol solution freezes (i.e. TG = 220 K). In the case of the powder, we blocked the dried nanowires inside an epoxy resin whose solidification is operational at room temperature.

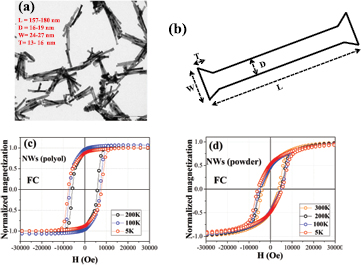

Figure 1. TEM image of Co nanowires having morphological parameters: L = 157–180 nm, D = 16–19 nm, W = 24–27 nm and T = 13–16 nm (a); sketch of morphological relevant parameters for Co nanowires (b); hysteresis cycles at different temperatures of the nanowires imaged inside their polyol solution (c) and as dried powder (d).

Download figure:

Standard image High-resolution image3. Results and discussion

Figure 1(a) presents the typical nanowires morphology observed in our systems by TEM. All the samples studied here are constituted of nanowires having a mean diameter (D) in the range of 17–26 nm and a mean length (L) of 89 nm up to 276 nm (see figure 1(b)). They present an elongated morphology with a mean thickness (T) of the head ranging between 11.2 to 52.3 nm and with a mean width (W) of 24 to 33 nm (see figure 1(b)). Morphology details can be also found in table 1.

Table 1. Morphology details (L/D, D/W and T) of several studied batches, magnetic parameters at low temperature (5 K) for both nanowires in their polyol solution and as dried powder.

| L/D | D/W | T (nm) | SQ powder | α powder | Mr/Ms | Hc (Oe) | Ms (emu g−1) | δ | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Polyol | Powder | Polyol | Powder | |||||||

| 4.29 | 0.77 | 12.86 | 0.42 | 2.39 | 0.65 | 0.621 | 7659 | 5231 | 157 | — |

| 6.38 | 0.69 | 11.84 | 0.21 | 2.21 | 0.53 | 0.455 | 6779 | 4954 | 136 | 0.082 |

| 7.34 | 0.75 | 14.17 | 0.27 | 1.05 | 0.64 | 0.48 | 6382 | 5790 | 133 | 0.063 |

| 9.16 | 0.88 | 11.20 | 0.23 | 2.73 | — | 0.44 | 6456 | 4120 | 149 | 0.074 |

| 10.26 | 0.65 | 19.73 | 0.31 | 2.43 | 0.87 | 0.53 | 7674 | 5640 | 169 | 0.050 |

| 10.70 | 0.78 | 52.36 | 0.28 | 1.27 | — | 0.48 | 7130 | 5240 | 143 | 0.056 |

| 12.23 | 0.74 | 18.86 | 0.27 | 1.90 | 0.76 | 0.48 | 7275 | 5769 | 141 | 0.054 |

We show typical observed normalized FC hysteresis loops in figures 1(c) and (d) respectively for the nanowires in their polyol solution and their corresponding dried powder. The squareness of the hysteresis loop of the polyol samples is better than the one of the corresponding powder. Considering the Mr/Ms ratio (i.e. the magnetic remanence at H = 0 Oe over the saturation magnetization), we found this ratio equal to 0.9 for the nanowires inside their polyol solution and equal to 0.5 for the corresponding blocked powder. This confirms the good alignment of the nanowires when they freeze in their synthesis solution under the application of a magnetic field [23]. In fact, in this latter condition, dipolar interactions between the nanowires are negligible and they are better dispersed. Thus the nanowires can easily align along the external magnetic field applied during the freezing leading to a higher squareness of the magnetic loop (i.e higher Mr/Ms ratio) [26]. The Mr/Ms ratio of 0.5 observed in the case of the powder confirms the random orientation of the nanowires blocked in the epoxy resin used to immobilize the particles during the measurements. Comparing all the measured hysteresis cycles, we could not verify the expected influence of the size and the shape of Co nanowires on their magnetic properties. As reported previously [23–25], the coercive behavior of the nanowires is expected to increase with the increase of the L/D ratio and it is supposed to show a non-linear behavior as a function of the thickness T. This suggested that, in our case, other parameters should be responsible for the observed magnetic properties. Good candidates have been proposed in the literature [12, 15] as the dispersion of the size and the stacking fault density. Thus, in order to detect the relevant parameter driving the magnetic behavior of these nanowires, we decided to calculate from the measured hysteresis loops the magnetic energy product for each batch (BHmax). We used the following equations reported in literature [18]:

where Br = 4πMrD (Gauss) is the magnetic flux density through the structure at the remanent state, D = 8.92 g cm−3 the cobalt bulk density, µ0 is the magnetic permeability of the vacuum, Hc (Oe) the measured coercive field and  (dimensionless). This latter coefficient shows how the magnetic energy product BHmax strongly depends on the squareness (SQ) of the nanowires hysteresis loop. The SQ is defined as

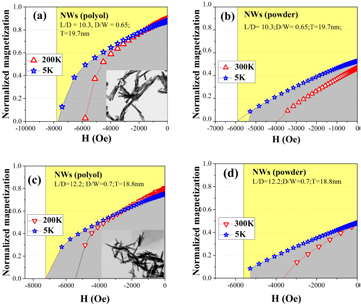

(dimensionless). This latter coefficient shows how the magnetic energy product BHmax strongly depends on the squareness (SQ) of the nanowires hysteresis loop. The SQ is defined as  , where A is the area under the second quadrant of the loop (see figure 2), Hc (Oe) and Ms (emu g−1) are respectively the coercive field and the magnetization at saturation. The final BHmax product has been converted from MGOe in the CGS system to kJ m−3 in the international system of units.

, where A is the area under the second quadrant of the loop (see figure 2), Hc (Oe) and Ms (emu g−1) are respectively the coercive field and the magnetization at saturation. The final BHmax product has been converted from MGOe in the CGS system to kJ m−3 in the international system of units.

Figure 2. The second quadrant of hysteresis loop for (a) Co nanowire in polyol with D (16–19 nm), L (157–180 nm), W (24–27 nm), T (13–16 nm) and the corresponding powder (b); second quadrant of hysteresis loop for (c) Co nanowire in polyol with D (18–21 nm), L (214–259 nm), W (22–25 nm), T (15–18 nm) and the corresponding powder (d).

Download figure:

Standard image High-resolution imageObviously, the calculation of the magnetization at saturation was possible only in the case of the powder samples which we could weigh before blocking into the epoxy. In the case of the nanowires in polyol we could not do this. To give a first estimation of the magnetic energy product also in this latter case, we decided to calculate the BHmax by using simple considerations on the measured hysteresis loops. For all our samples the condition μ0Hc ⩾ Br/[2(1 + α)] is verified. It can be deduced from equation (1) that the ratio between the magnetic energy product of the same batch of nanowires inside their synthesis solution to the one of their corresponding dried powder  is proportional to the ratio between the corresponding areas under the hysteresis loop in the second quadrant (grey area in figure 2). So after normalizing the hysteresis curves in order to make them comparable, we easily deduced the ratio of those areas:

is proportional to the ratio between the corresponding areas under the hysteresis loop in the second quadrant (grey area in figure 2). So after normalizing the hysteresis curves in order to make them comparable, we easily deduced the ratio of those areas:

where Spolyol, Spowder are the area under the second quadrant of the hysteresis curve respectively of nanowires in polyol and their corresponding powder samples. Figures 2(a) and (c) show a normalized second quadrant for two different batches of nanowires inside their synthesis solution both at high and low temperatures. A normalized second quadrant of the corresponding powders is shown in figures 2(b) and (d). From figure 2, it is easy to deduce that the area under the curve decreases considerably when the nanowires are dried (in powders). This behavior can be attributed to the random alignment and high dipolar interactions of the latter compared to their corresponding nanowires inside the polyol solution. As the Mr/Ms ratio and the Hc strongly affect the BHmax value, we expect the alignment and dispersion of the nanowires to be key parameters to improve the magnetic energy product. In fact, as presented before, the BHmax in equations (1) and (2) strongly depends on the squareness of the hysteresis loop and thus from the area under the second quadrant of this cycle. We found that for a quite equal diameter in the middle of the nanowire (D = 16–21 nm), the squareness value of the second quadrant is not higher in the case of the longer nanowire (L = 214–259 nm) compared to (L = 157–180 nm) (see figures 2(a) and (c)), suggesting again that a more relevant parameter is playing an important role on the magnetic energy product instead of the morphology.

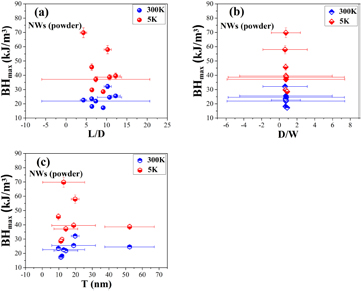

It has already been reported [23] that the shape's parameters drive not only the coercive field but also the easiness of the alignment of the nanowires. Thus our results seem to go against these previous observations. In order to go deeper into this odd shape effect observed over the magnetic energy product, we studied the BHmax behavior as a function of the relevant morphological parameter (i.e. L/D, D/W and T) (shown in figure 3). It is important to underline that we show here only the morphology results for nano-powder samples, as we found exactly the same trend for the corresponding nanowires inside the synthesis solution. Thus, these latter results would be redundant.

Figure 3. BHmax as a function of (a) L/D, (b) D/W and (c) T. The non-homogeneity of the nanowires was a reason for reducing the BHmax.

Download figure:

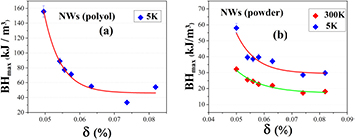

Standard image High-resolution imageAs expected, better performances of the magnetic energy product are obtained at low temperature (figure 3) for each morphology. This cannot be attributed to the shape contribution to the reversal mechanism of the nanowires (i.e. Hshape) as this doesn't change in function of temperature. Considering a simple model in which the shape anisotropy contribution to the coercive field of the nanowires is added to the magnetocrystalline contribution (i.e. Hc ~ Hshape + HMC, being HMC = 2K1/Ms) [16, 23], then a higher value of the magnetocrystalline anisotropy constant (k1) expected at low temperature will lead to a higher value of the coercive field [16]. As a result, a higher magnetic energy product is observed at low temperature. The striking feature of the graphs in figure 3 is the absence of any clear dependence of the magnetic energy product to the morphology variations, strongly suggesting that a more relevant parameter is driving the magnetic energy of the hcp Co nanowires. Also, comparing our results with the literature we cannot again see any coherence between the magnetic energy product value and the polydispersity of nanowires size [18]. In our case, the poly-dispersed nanowires (see big error bars in figure 3) do not present the lowest magnetic energy value. It is worth noting that our higher magnetic energy product at room temperature is significantly lower (35 kJ m−3) than the highest values achieved in [18] (i.e. 350 kJ m−3 for monodispersed cobalt nano-powders and 278.5 kJ m−3 for the poly-dispersed one). To go further, we reported in figure 4 the BHmax dependence on the stacking fault density δ for both nanowires inside their polyol solutions (figure 4(a)) and the corresponding powder (figure 4(b)). This density has been calculated for each batch by XRD analysis [19] (details are reported elsewhere [22]). As stated previously [9–14], the stacking fault density, δ, strongly affects the magnetocrystalline anisotropy of Co hcp nanowires. Sokalski et al [12], reported on an important decrease (exponential-like decay) of the magnetocrystalline anisotropy constant with the increasing of stacking fault density in cobalt thin films. Looking into our results in figures 4(a) and (b), we found the exponential decay being coherent also in the case of nano-objects (green and red lines).

Figure 4. BHmax of Co nanowires as a function of stacking fault density, (a) polyol sample, (b) powder sample. The lines (green and red for 300 K and 5 K, respectively) are exponential fits showing the rapid decrease of BHmax with the increasing of stacking fault density.

Download figure:

Standard image High-resolution imageThe striking feature in figure 4 is that, no matter what the dispersion and morphology of the nanowires, the stacking fault density drives exponentially the collapse of the magnetic energy product. The exponential decay factor c (BHmax = Ae−x/c where x is the stacking fault density) is expected to be affected by the dipolar interactions between nanowires. We could observe a more rapid decay (i.e. higher c) in the case of more interacting nanowires.

4. Conclusion

We succeeded in investigating the effect of stacking faults over the magnetic energy product behavior in hcp-cobalt nanowires. We compared Co nanowires showing hexagonal crystal symmetry, various sizes and shapes, and different density values of grown faults. The experimental study of the static magnetic properties confirmed that the reversal mechanism in these nanowires depends on both morphological characteristics and structural defects. The magnetic energy product (BHmax) behavior as a function of the relevant morphological parameter (i.e. L/D, D/W and T) shows better performances at low temperature for each morphology. A higher magnetic energy product is observed at low temperature due to the magnetocrystalline anisotropy contribution to the reversal mechanisms of the nanowires magnetization. The striking feature is the absence of any clear dependence of the magnetic energy product to the morphology variations, strongly suggesting that a more relevant parameter is driving the magnetic energy of the hcp Co nanowires. We found that no matter what the dispersion and morphology of the nanowires, the stacking faults play a key role on the observed collapse of the magnetic energy product values. The higher the stacking faults defects, the lower the magnetic energy product.

Acknowledgments

H T T Nong thanks USPC IDEX Project ArchiMEdes for the PhD grant support. The magnetic measurements at ESPCI have been supported through Grants from Region Ile-de-France. Agence Nationale de la Recherche and Commissariat à l'Investissement d'Avenir are gratefully acknowledged for their financial support of this work through Labex SEAM (Science and Engineering for Advanced Materials and Devices), ANR 11 LABX 086, ANR 11 IDEX 05 02.5.

Footnotes

- *

Oral talk at 8th International Workshop on Advanced Materials Science and Nanotechnology (IWAMSN2016), 8–12 November 2016, Ha Long City, Vietnam.