Abstract

In this work, we investigated the influence of concentration of the additional nanoparticles of  and

and  on the coercivity of the sintered

on the coercivity of the sintered  magnets. Composition and concentration of the additional compounds clearly influence magnetic properties of the magnets. The coercivity

magnets. Composition and concentration of the additional compounds clearly influence magnetic properties of the magnets. The coercivity  increases linearly from

increases linearly from  to

to  with increasing the weight fraction of the

with increasing the weight fraction of the  nanoparticles from 0 to

nanoparticles from 0 to  . Meanwhile, the

. Meanwhile, the  of the

of the  added magnets reaches a maximal value of

added magnets reaches a maximal value of  at the optimum addition of

at the optimum addition of  . The quite high maximum energy products,

. The quite high maximum energy products,  , were also obtained for the magnets added with the nanoparticles.

, were also obtained for the magnets added with the nanoparticles.

Export citation and abstract BibTeX RIS

Original content from this work may be used under the terms of the Creative Commons Attribution 3.0 licence. Any further distribution of this work must maintain attribution to the author(s) and the title of the work, journal citation and DOI.

1. Introduction

The further enhancement of magnetic properties and optimization of fabrication technology of anisotropic sintered Nd–Fe–B magnets are still concerned to study because this kind of magnets is more and more applied in practice, especially for generators and vehicle motors [1, 2]. However, the temperature of the sintered Nd–Fe–B magnets in the motors and generators is high ( ) during operating time [3]. When increasing temperature, the coercivity of the magnets is decreased rapidly due to the thermal demagnetization, leading to the reduction of efficiency in the high-temperature environments. In order to enhance the

) during operating time [3]. When increasing temperature, the coercivity of the magnets is decreased rapidly due to the thermal demagnetization, leading to the reduction of efficiency in the high-temperature environments. In order to enhance the  of the Nd–Fe–B magnets to meet the application requirements in these devices, Dy is usually replaced partially for Nd [4–6]. However, Dy is expensive and scarce. Therefore, a number of scientists have been investigating to improve the quality of the sintered Nd–Fe–B magnets without using or using a small amount of the heavy rare earth element. Previous works have indicated that the coercivity of this type of Nd–Fe–B magnets can be enhanced by addition of some elements other than the main components of Nd, Fe and B such as Al, Cu, Co... or by improving technology [7–10]. Especially, the addition of non-ferromagnetic compounds to grain boundary not only enhances the coercivity but also reduces amount of heavy rare earth [11–16]. Each additional compound contains the elements which differently affect to the magnetic properties of the magnets. With Dy-addition, the coercivity is significantly increased because the anisotropy field

of the Nd–Fe–B magnets to meet the application requirements in these devices, Dy is usually replaced partially for Nd [4–6]. However, Dy is expensive and scarce. Therefore, a number of scientists have been investigating to improve the quality of the sintered Nd–Fe–B magnets without using or using a small amount of the heavy rare earth element. Previous works have indicated that the coercivity of this type of Nd–Fe–B magnets can be enhanced by addition of some elements other than the main components of Nd, Fe and B such as Al, Cu, Co... or by improving technology [7–10]. Especially, the addition of non-ferromagnetic compounds to grain boundary not only enhances the coercivity but also reduces amount of heavy rare earth [11–16]. Each additional compound contains the elements which differently affect to the magnetic properties of the magnets. With Dy-addition, the coercivity is significantly increased because the anisotropy field  of

of  of

of  at room temperature is much higher than that of

at room temperature is much higher than that of  ,

,  . In addition, the adding Dy also avoids oxygenation for the magnets. However, antiferromagnetic coupling with Fe leads to reduction of remanence

. In addition, the adding Dy also avoids oxygenation for the magnets. However, antiferromagnetic coupling with Fe leads to reduction of remanence  and the maximum energy product

and the maximum energy product  . It is known that the coercivity of the sintered Nd–Fe–B magnets is sensitive to the microstructure. The addition of Al-containing compounds can improve microstructure such as smoothness of grain boundaries, uniformity of the particles of the magnets [17–19]. Pandian et al reported that the addition of Al of

. It is known that the coercivity of the sintered Nd–Fe–B magnets is sensitive to the microstructure. The addition of Al-containing compounds can improve microstructure such as smoothness of grain boundaries, uniformity of the particles of the magnets [17–19]. Pandian et al reported that the addition of Al of  decreases remanence

decreases remanence  of

of  but increases the coercivity

but increases the coercivity  of about

of about  .

.

Our previous study reported that, by adding  of

of  nanoparticles to grain boundaries, the coercivity of the magnets could be considerably improved [20]. In this work, we investigated the influence of weight fractions of the additional nanoparticles of

nanoparticles to grain boundaries, the coercivity of the magnets could be considerably improved [20]. In this work, we investigated the influence of weight fractions of the additional nanoparticles of  and

and  on the coercivity of the sintered Nd–Fe–B magnets.

on the coercivity of the sintered Nd–Fe–B magnets.

2. Experimental

The pre-alloys of  were prepared from Nd, Fe and FeB by induction melting under Ar gas to avoid oxidation. The obtained ingots were pulverized for 8 h to obtain powder with grain size of

were prepared from Nd, Fe and FeB by induction melting under Ar gas to avoid oxidation. The obtained ingots were pulverized for 8 h to obtain powder with grain size of  by ball milling method in industrial white gasoline. The addition alloys

by ball milling method in industrial white gasoline. The addition alloys  and

and  were prepared by arc-melting furnace under argon atmosphere. After that the resulted alloys were pulverized by high energy ball milling method with milling time of 4 h to obtain nanoparticles with average size of about 50 nm. The solvent/material and ball/powder ratios are

were prepared by arc-melting furnace under argon atmosphere. After that the resulted alloys were pulverized by high energy ball milling method with milling time of 4 h to obtain nanoparticles with average size of about 50 nm. The solvent/material and ball/powder ratios are  and

and  , respectively. The additional nanoparticles with various weight fractions from 1 to 5% were mixed into the Nd–Fe–B powder thoroughly. The mixed powder was pressed under a pressure of 15 MPa in an oriented magnetic field of about

, respectively. The additional nanoparticles with various weight fractions from 1 to 5% were mixed into the Nd–Fe–B powder thoroughly. The mixed powder was pressed under a pressure of 15 MPa in an oriented magnetic field of about  . The pressed magnets were sintered at

. The pressed magnets were sintered at  for 1 h. A two-stage heat treatment process was chosen and carried out using a vacuum furnace. At the first stage, the magnets were heat-treated at

for 1 h. A two-stage heat treatment process was chosen and carried out using a vacuum furnace. At the first stage, the magnets were heat-treated at  for 1 h and then rapidly quenched to room temperature by argon atmosphere. For the second stage, the magnets were heat-treated at

for 1 h and then rapidly quenched to room temperature by argon atmosphere. For the second stage, the magnets were heat-treated at  for 1 h and rapidly quenched by argon atmosphere. For both the stages, the heating and quenching rates were

for 1 h and rapidly quenched by argon atmosphere. For both the stages, the heating and quenching rates were  and

and  , respectively. The structure of the samples was thoroughly analyzed by using scanning electron microscope (SEM). The specimens of cylinders with 3 mm diameter and 3 mm height were cut to investigate magnetic properties on a pulsed high field magnetometer. In order to determine the maximum energy product

, respectively. The structure of the samples was thoroughly analyzed by using scanning electron microscope (SEM). The specimens of cylinders with 3 mm diameter and 3 mm height were cut to investigate magnetic properties on a pulsed high field magnetometer. In order to determine the maximum energy product  of the magnets, a demagnetization factor was estimated through a semi-experimental data sheet.

of the magnets, a demagnetization factor was estimated through a semi-experimental data sheet.

3. Results and discussion

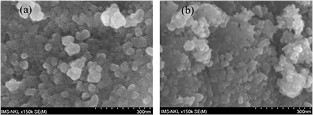

Figure 1 shows the SEM images of powder of the additional compounds with milling time of 4 h. We can see that the particles of the samples are relatively uniform with the average size smaller than 50 nm. However, for both the samples still contains region which is difficult to observe individual grains by their coalescence. With high surface energy, the first melting of nanoparticles during sintering process makes homogeneous distribution of the intergranular phase, leading to a decrease of exchange interaction of the  grains [21]. This is one of the reasons for the enhancement of coercivity

grains [21]. This is one of the reasons for the enhancement of coercivity  and maximum energy product

and maximum energy product  . Nano-scale sized particles are desired to mix with the Nd–Fe–B micropowder.

. Nano-scale sized particles are desired to mix with the Nd–Fe–B micropowder.

Figure 1. SEM images of the  (a) and

(a) and  (b) powder with milling time of 4 h.

(b) powder with milling time of 4 h.

Download figure:

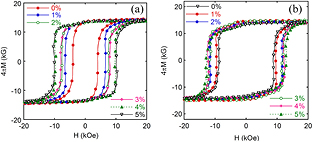

Standard image High-resolution imageFigures 2 and 3 show the hysteresis loops of the magnets added with various weight fractions of  and

and  nanoparticles before and after heat treatment. We can realize that, the coercivity of the magnets depends on both the nanoparticle addition and heat treatment process. The influence of addition of

nanoparticles before and after heat treatment. We can realize that, the coercivity of the magnets depends on both the nanoparticle addition and heat treatment process. The influence of addition of  nanoparticles is stronger than that of

nanoparticles is stronger than that of  ones. With the

ones. With the  added magnets, the change of the coercivity on large concentration of nanoparticles is not considerably. After heat treatment the coercivity was significantly enhanced. This probably is due to the improvement of microstructure of the magnets after heat treatment such as controlling particles size, creating the suitable grain boundary phase... However, the squareness of the hysteresis loops of the magnets is slightly decreased. A little dip was observed in the second quadrant demagnetization curves of the annealed magnets. This can be explained by the wide distribution of the grain size after heat treatment. At the same time, the addition of elements can change the structure and distribution of phases, leading to the inhomogeneity of demagnetization field. On the other hand, heterogeneous grain boundaries can lead to the formation of the soft magnetic α-Fe phase which plays a role as nucleation centre of reversal domains to cause magnetization of the magnets at lower external magnetic field [22].

added magnets, the change of the coercivity on large concentration of nanoparticles is not considerably. After heat treatment the coercivity was significantly enhanced. This probably is due to the improvement of microstructure of the magnets after heat treatment such as controlling particles size, creating the suitable grain boundary phase... However, the squareness of the hysteresis loops of the magnets is slightly decreased. A little dip was observed in the second quadrant demagnetization curves of the annealed magnets. This can be explained by the wide distribution of the grain size after heat treatment. At the same time, the addition of elements can change the structure and distribution of phases, leading to the inhomogeneity of demagnetization field. On the other hand, heterogeneous grain boundaries can lead to the formation of the soft magnetic α-Fe phase which plays a role as nucleation centre of reversal domains to cause magnetization of the magnets at lower external magnetic field [22].

Figure 2. Hysteresis loops of the magnets added with various fractions of nanoparticles of  before (a) and after (b) heat treatment.

before (a) and after (b) heat treatment.

Download figure:

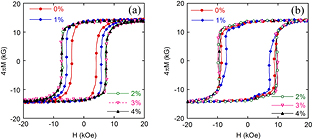

Standard image High-resolution imageFigure 3. Hysteresis loops of the magnets added with various fractions of nanoparticles of  before (a) and after (b) heat treatment.

before (a) and after (b) heat treatment.

Download figure:

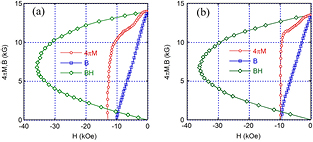

Standard image High-resolution imageMagnetic characteristic curves of the heat-treated magnets added with  of

of  and

and  of

of  are presented in figure 4. The obtained results show that, the coercivity of the magnets added with

are presented in figure 4. The obtained results show that, the coercivity of the magnets added with  is higher than that of the one added with

is higher than that of the one added with  . However, the squareness of hysteresis loop of the former is worse than that of the latter one, leading to the decrease of maximum energy product

. However, the squareness of hysteresis loop of the former is worse than that of the latter one, leading to the decrease of maximum energy product  , which has been obtained to be 36 MGOe and 37 MGOe, respectively. In general, the enhancement both the coercivity

, which has been obtained to be 36 MGOe and 37 MGOe, respectively. In general, the enhancement both the coercivity  and the maximum energy product

and the maximum energy product  of the magnets is difficult. Because the magnetic properties of the magnets are not only dependent on

of the magnets is difficult. Because the magnetic properties of the magnets are not only dependent on  phase, but also on the microstructure. Optimization of microstructure depends on parameters of technological conditions such as particle size, sintering temperature, sintering time, annealing time, annealing temperature... Controlling of manufacture technology to create the sintered magnets with suitable magnetic properties for practical applications is required.

phase, but also on the microstructure. Optimization of microstructure depends on parameters of technological conditions such as particle size, sintering temperature, sintering time, annealing time, annealing temperature... Controlling of manufacture technology to create the sintered magnets with suitable magnetic properties for practical applications is required.

Figure 4. Magnetic characteristic curves of the heat-treated magnets added with  of

of  (a) and 3 wt%

(a) and 3 wt%  (b) nanoparticles.

(b) nanoparticles.

Download figure:

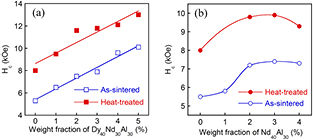

Standard image High-resolution imageFigure 5 shows the dependences of the coercivity  of the magnets on various weight fractions of nanoparticles of

of the magnets on various weight fractions of nanoparticles of  and

and  before and after heat treatment. We can see that

before and after heat treatment. We can see that  depends almost linearly on the concentration of

depends almost linearly on the concentration of  (figure 5(a)). Its value increases from 5.3 to

(figure 5(a)). Its value increases from 5.3 to  for the as-sintered magnets and from 8 to

for the as-sintered magnets and from 8 to  for the heat-treated magnets when weight fractions of

for the heat-treated magnets when weight fractions of  nanoparticles increases from 0 to 5%. This is agreed with the result reported by Liu et al [6]. The coercivity enhancement of the magnets added with Dy-containing compounds is due to Dy diffusion from the grain boundaries to the

nanoparticles increases from 0 to 5%. This is agreed with the result reported by Liu et al [6]. The coercivity enhancement of the magnets added with Dy-containing compounds is due to Dy diffusion from the grain boundaries to the  grain during sintering and heat treatment process, leading to the formation of the

grain during sintering and heat treatment process, leading to the formation of the  shell. Because

shell. Because  of

of  is higher than that of

is higher than that of  , the formation

, the formation  shell might make magnetic anisotropy of the outer layer higher than that of the interior. As a result, the formation and propagation of a reverse domain would be inhibited more than in the normal grains. When the reverse nucleations are inhibited at the surface of the grains, an external magnetic field must be large enough for the formation and growth of them, meaning that the magnets have high coercivity. However, the effect of the coercivity enhancement for the magnets by adding

shell might make magnetic anisotropy of the outer layer higher than that of the interior. As a result, the formation and propagation of a reverse domain would be inhibited more than in the normal grains. When the reverse nucleations are inhibited at the surface of the grains, an external magnetic field must be large enough for the formation and growth of them, meaning that the magnets have high coercivity. However, the effect of the coercivity enhancement for the magnets by adding  nanoparticles in this work is weaker than that obtained in our previous investigation [20]. This probably is due to the change of milling solvent, whose contaminations might affect to the quality of the additional nanoparticles.

nanoparticles in this work is weaker than that obtained in our previous investigation [20]. This probably is due to the change of milling solvent, whose contaminations might affect to the quality of the additional nanoparticles.

Figure 5. Dependence of coercivity  of magnets added with various weight fractions of nanoparticles of

of magnets added with various weight fractions of nanoparticles of  (a) and

(a) and  (b) before and after heat treatment.

(b) before and after heat treatment.

Download figure:

Standard image High-resolution imageAs for the magnets added with  nanoparticles, their coercivity slightly increases from 5.3 to

nanoparticles, their coercivity slightly increases from 5.3 to  before heat treatment, and from 8 to

before heat treatment, and from 8 to  after heat treatment as weight fraction of the additional compound increases from 0 to 3% (figure 5(b)). After that, the

after heat treatment as weight fraction of the additional compound increases from 0 to 3% (figure 5(b)). After that, the  decreases when the additional fraction is further increased. Thus, the optimal additional weight fraction of

decreases when the additional fraction is further increased. Thus, the optimal additional weight fraction of  nanoparticles is 3%. The increase of the coercivity is good agreement with the result reported by Mottram et al [19]. The formation of disadvantage phases at grain boundaries is reason for reduction of the coercivity with additional fractions of 4%. On the other hand, the optimal sintering temperature might be changed by large fraction of the additional compound, which has melting temperature far from that of the Nd–Fe–B phase, leading to the undesired microstructure for the magnets.

nanoparticles is 3%. The increase of the coercivity is good agreement with the result reported by Mottram et al [19]. The formation of disadvantage phases at grain boundaries is reason for reduction of the coercivity with additional fractions of 4%. On the other hand, the optimal sintering temperature might be changed by large fraction of the additional compound, which has melting temperature far from that of the Nd–Fe–B phase, leading to the undesired microstructure for the magnets.

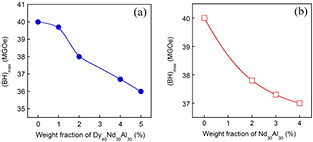

The dependence of maximum energy product  of the heat-treated magnets on various additional fractions of the

of the heat-treated magnets on various additional fractions of the  and

and  nanoparticles is shown in figure 6. We can see that, the

nanoparticles is shown in figure 6. We can see that, the  decreases with increasing the fraction of both the additional compounds, agreeing with the results reported in [12]. The reduction of the

decreases with increasing the fraction of both the additional compounds, agreeing with the results reported in [12]. The reduction of the  of the added magnets is due to a decrease of saturation magnetization by additional of non-ferromagnetic nanoparticles. Although the

of the added magnets is due to a decrease of saturation magnetization by additional of non-ferromagnetic nanoparticles. Although the  is reduced but its value is still high enough (

is reduced but its value is still high enough ( ) for practical application. Especially, the enhancement of the coercivity is necessary for electric generators and motors. On the other hand, the less use or unused of the heavy rare earth of Dy is important for lowering the cost of the magnets.

) for practical application. Especially, the enhancement of the coercivity is necessary for electric generators and motors. On the other hand, the less use or unused of the heavy rare earth of Dy is important for lowering the cost of the magnets.

Figure 6. Dependence of maximum energy product  of the heat-treated magnets added with various fractions of

of the heat-treated magnets added with various fractions of  (a) and

(a) and  (b) nanoparticles.

(b) nanoparticles.

Download figure:

Standard image High-resolution image4. Conclusion

The influence of concentration of the additional nanoparticles of  and

and  on the coercivity

on the coercivity  of the sintered

of the sintered  magnets has been investigated. The

magnets has been investigated. The  is considerably improved by adding nanoparticles to the grain boundaries of magnets. The effect of the

is considerably improved by adding nanoparticles to the grain boundaries of magnets. The effect of the  nanoparticles on the coercivity enhancement for the magnets is stronger than that of the

nanoparticles on the coercivity enhancement for the magnets is stronger than that of the  ones. While the

ones. While the  reaches a maximal value of

reaches a maximal value of  at

at  of

of  addition, it increases linearly from

addition, it increases linearly from  to

to  with increasing the weight fraction of the

with increasing the weight fraction of the  nanoparticles from 0 to 5%. The

nanoparticles from 0 to 5%. The  of the magnets is still retained high enough (

of the magnets is still retained high enough ( ). The obtained hard magnetic parameters of the magnets can be applied in practice.

). The obtained hard magnetic parameters of the magnets can be applied in practice.

Acknowledgments

This work was supported by Vietnam Academy of Science and Technology under Grant number of VAST03.05/16-17. Most of experiments were done in the Key Laboratory for Electronic Materials and Devices, Institute of Materials Science, Vietnam Academy of Science and Technology, Viet Nam.